Smart Circular Economy: Digitalization Revolutionizing Circular Economy

The demand for a sustainable and resilient economy is steadily increasing – especially in light of resource scarcity, regulatory requirements, and rising societal expectations. The smart circular economy offers a forward-looking approach. But what exactly does it entail, which technologies are crucial, and what specific benefits does it offer companies?

Key Takeaways

- Smart Circular Economy links circular value creation with digital technologies

- The goal is efficient, transparent, and automated resource use across the entire product lifecycle

- Practical examples and use cases show: Smart Circular Economy is a strategic lever for sustainable competitiveness

What Does “Smart Circular Economy” Mean?

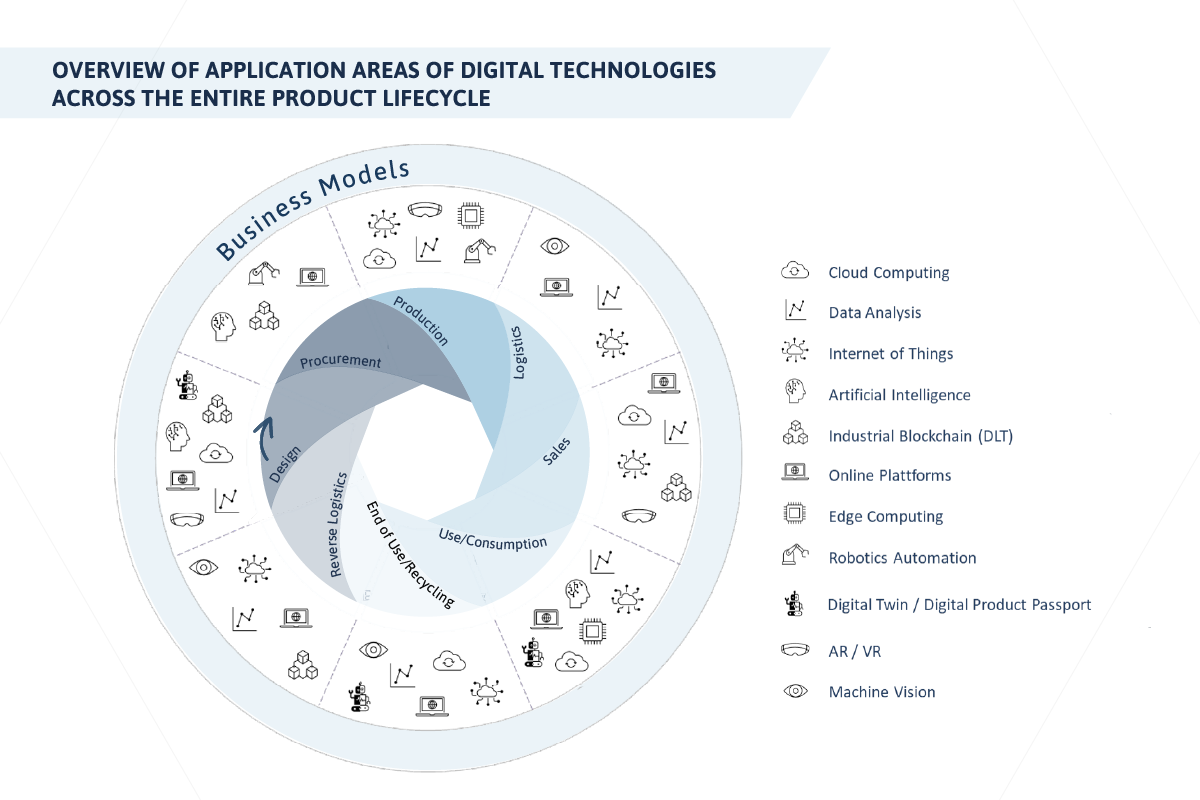

The smart circular economy refers to the the synergistic integration of digital technologies with the principles of circular value creation. By embedding digital solutions into circular processes, new potential emerges to increase efficiency, transparency, and scalability.

While the circular economy focuses on R-strategies such as reuse, repair, remanufacturing, or recycling, the smart version expands this scope through data-driven, connected, and automated processes.

The aim of Smart CE

The goal is to optimize resource use across all phases of the product lifecycle and systematically reduce environmental impacts. Smart CE represents an optimization approach that views digitalization as an enabler of an effective and scalable circular economy.

Elements of Smart CE

Data Transparency Across the Product Lifecycle

A core element of smart circular systems is end-to-end transparency regarding materials, components, and usage states. Technologies enable real-time tracking and condition monitoring of products, creating data-based access to key information.

Circular Design and Usage Intensification

The integration of digital technologies into product development opens up new potential for systematically aligning industrial value creation with circular principles. Even in the early design phase, simulation-based tools enable well-informed decisions regarding material selection, product architecture, and recyclability. Building on the principles of ecodesign, this creates a solid technical foundation for circular strategies.

Digital Infrastructures and Services Supporting Circular Processes

Digital infrastructures and services are key components of circular value creation systems. They enable continuous monitoring, analysis, and control of material and product flows across the entire lifecycle.

The Role of Digitalization in the Circular Economy

Digitalization is a central enabler of circular business models. It allows real-time monitoring, control, and optimization of material and product flows – forming the basis for data-driven decision-making throughout the entire product lifecycle.

Relevant key technologies include:

IoT & Sensors for Waste Sorting and Maintenance

IoT systems and smart sensors automatically detect states and material types. Optical sensors in recycling facilities accurately identify waste materials (e.g., plastics, metals), increasing sorting quality and speed. Embedded product sensors enable early fault detection and facilitate efficient maintenance.

Artificial Intelligence & Data Analytics

Artificial Intelligence (AI) can be applied throughout circular value chains by analyzing large datasets, identifying patterns, and providing informed decision-making tools. In design, AI supports simulations of circular alternatives; in procurement, it enables precise demand forecasting to avoid overproduction and waste. It also helps detect supply chain bottlenecks and optimize logistics and production (see more in the EFS Consulting AI Use Cases here).

Digital Twins & Lifecycle Management

Digital twins are virtual representations of physical products, including all lifecycle data. They can simulate real system behavior and detect non-measurable variables during manufacturing. An active twin allows bidirectional data exchange between the real process and its virtual model. Combined with Product Lifecycle Management (PLM), the digital twin becomes a core component of integrated data and process management across the entire product lifecycle. Simulations under variable usage scenarios support precise performance evaluations and form the basis for adaptive, condition-based maintenance.

Blockchain & Traceability

Blockchain enables decentralized, tamper-proof storage and transfer of information without central authority. Every transaction is documented, validated, and permanently added to the chain. This enables transparent traceability of products and materials across the entire value chain – from raw material sourcing to recycling. Advantages include reduced counterfeiting and fraud, proof of origin and material quality, increased logistical efficiency, and traceable product pathways supporting circular value creation..

Challenges of Digitalizing Circular Systems

Despite the great potential of digital technologies, numerous challenges persist in implementing them in circular systems. Technical hurdles such as lack of interoperability, poor data quality, and missing standards hinder cross-company integration. Organizational barriers – such as silo structures, skill shortages, or limited digital maturity – also pose key obstacles.

Legal uncertainties, especially regarding data protection, data sovereignty, and liability, further complicate trusted data exchange. Effective digitalization of the circular economy requires integrated approaches that address technological, organizational, and regulatory conditions comprehensively.

Smart CE Use Cases & Industry Applications

Circular Business Models, Platforms & Industrial Best Practices

Digital technologies enable innovative circular business models focused on resource efficiency, extended product usage, and closed-loop systems. Models like the sharing economy, leasing, or Product-as-a-Service (PaaS) use digital interfaces to capture usage data, condition states, and return processes. This allows for more intensive product use, optimized maintenance, and automated returns.

Digital secondary raw material platforms also improve material allocation by matching supply and demand across markets, increasing transparency, and reducing transaction costs. One example is SECONTRADE, a Europe-wide digital marketplace.

Circularise, another example, offers an advanced traceability platform that strengthens operational resilience and supports compliance and risk management in complex supply chains. It enables secure transmission of sustainability and material data along the entire value chain – enabling auditable, data-based decisions aligned with ecological and economic goals..

These smart applications enhance the economic attractiveness and scalability of circular business models – a key lever for transforming toward a resource-efficient, data-driven circular economy.

Digitales Recycling

Despite technological advances, challenges remain – especially in waste sorting. Improper sorting (e.g., at household level) significantly complicates downstream recycling processes and leads to higher costs. As a result, many materials are not materially recycled but used for energy recovery or landfilled, permanently removing valuable raw materials from the loop.

Digital technologies offer new solutions: optical sensors, for example, enable automated identification and sorting of materials (e.g., plastics), improving recycling efficiency and quality. Automated sorting also reduces hazardous work for waste sector employees. RecyclingMonitor has developed a software solution focused on digitalizing and improving efficiency in the recycling industry, emphasizing simple system integration and intuitive user experience.

Digital Product Passport (DPP)

A key element for operationalizing circular business models and data-driven value creation is the Digital Product Passport (DPP). It provides a unified basis for recording and sharing product-related information across the EU. Starting in 2027, it will be mandatory for numerous product groups, including batteries, textiles, electronics, furniture, as well as steel and aluminum products. The DPP will contain information on material composition, carbon footprint, recycled content, repairability, lifespan, and disposal. This creates a standardized data foundation that promotes transparency, compliance, and sustainability along the supply chain, while building trust throughout the entire product lifecycle.

EFS Circular Economy Experts on the Business Opportunities of Smart CE

The Smart Circular Economy opens up new potential for efficiency, innovation, and sustainability. Digital technologies create transparency along the product lifecycle and enable data-driven business models such as Product-as-a-Service or digital secondary raw material markets. Our consulting practice at EFS Consulting shows: companies that adopt smart CE solutions early not only improve resource efficiency but also strengthen their competitiveness and organizational resilience.

EFS Consulting supports you in identifying tailored digital solutions for circular value creation and strategically integrating them into existing processes – with the goal of implementing Smart Circular Economy in a practical and impactful way. Contact us today for an initial, non-binding consultation!

FAQs

What is Smart Circular Economy?

Smart Circular Economy links circular economy with digital technologies. The goal is automated, efficient, and transparent resource use across the entire product lifecycle

Which technologies are relevant for digital circular economy?

Key technologies include IoT, AI, digital twins, and blockchain. They enable data transparency, condition monitoring, process optimization, and traceability.

How do companies benefit from digital circular economy?

Companies increase resource efficiency, reduce costs, and unlock new business models. Digital solutions enhance transparency and support sustainable competitiveness.