Measuring Circular Economy: Key Indicators and Methods

The systematic measurement of circularity is becoming increasingly important in the course of the sustainable transformation of the economy and society. Against the backdrop of regulatory developments and growing ecological challenges, the question of how to effectively assess and manage circular measures is coming into focus. This insight article highlights the fundamentals of measuring success in the circular economy, presents key indicators and assessment approaches, and outlines the challenges associated with capturing circular performance.

Key Takeaways

- Assessing the circular economy requires standardized indicators and KPIs in order to make circular progress objectively measurable and comparable.

- Circular economy (CE) indicators must be systemic, life cycle-oriented, practice-oriented, and must be based on robust data.

- In practice, inconsistent assessment frameworks, data gaps, and heterogeneous stakeholder interests complicate implementation.

- Methods such as material flow analyses, life cycle assessments, maturity models, and digital technologies broaden the assessment perspective and improve data quality.

Fundamentals of Measuring the Circular Economy

The transition to a circularity represents a profound change in the way natural resources are managed. This transformation is driven by ecological challenges such as climate change, dwindling raw materials, and the loss of biodiversity. In order to shape this change effectively, a systematic measurement of the success of circular measures is essential—both for companies and for policymakers and the scientific community.

Particularly at the corporate level, assessing circular performance is challenging because it takes into account not only economic but also ecological and social factors. To objectively assess and compare progress, standardized metrics and key performance indicators (KPIs) are needed. These serve to evaluate internal company developments and derive success models. The analysis focuses primarily on the product and company level, while macroeconomic perspectives remain outside the scope.

Requirements for and Characteristics of Circular Economy Indicators

Measuring circular value creation requires reliable indicators. But what actually makes a “good” indicator? Regardless of the specific definition, certain requirements should be met:

- Align with the principles of the circular economy — that is, be based on a systemic view of the entire value chain.

- Take a life cycle perspective — including appropriate temporal and spatial boundarie.

- Capture both direct resource use and the systemic impacts of transitioning to circular processes — for example, through specifically defined circularity metrics or complementary tools such as life cycle assessment (LCA)

Beyond these, it is crucial that CE indicators provide real added value in practice. They should therefore:

- Be SMART — that is, specific, measurable, accepted, realistic, and time-bound in order to be easily understood and transparent for all stakeholders.

- Be based on robust, preferably standardized data — incorporating diverse data sources such as internal company data, supply chain information, or open data.

- Ensure data availability — particularly with regard to the regularity, quality, and accessibility of the relevant information.

- Enable comparisons — for example, between products, companies, or systems, to facilitate benchmarking, best practices, and progress measurement.

Challenges and Limitations of Measurability

Despite numerous existing methods, the practical assessment of circular value creation remains demanding. A central problem is the lack of uniform indicator systems and a clearly defined assessment framework.

In practice, there is a wide variety of approaches to capturing resource use and circularity. This methodological diversity leads to inconsistencies and particularly hampers cross-industry or cross-company comparisons.

Small and medium-sized enterprises (SMEs) often face organizational and financial barriers, for example when implementing suitable measurement tools. Larger companies, on the other hand, are often constrained by regulatory requirements — e.g., when scaling circular business models.

Added to this is a heterogeneous stakeholder landscape: differing expectations and interests — from suppliers to customers to investors — make it difficult to establish a common basis for assessment.

Key CE Indicators from Literature & Practice

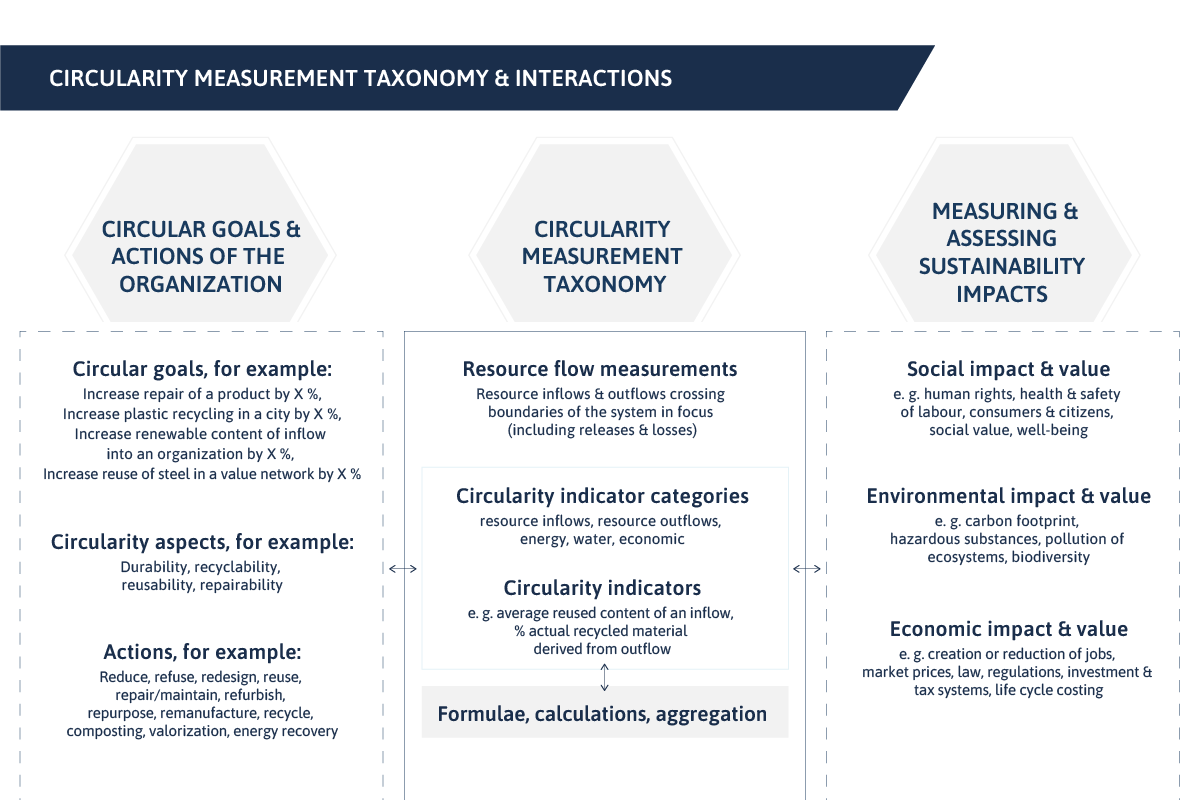

The early definition of ambitious and clearly formulated goals is a fundamental prerequisite for systematic performance monitoring. Targeted transformation management requires effective monitoring based on quantifiable indicators as well as regular reports on the progress toward achieving these goals. Against this backdrop, circular strategies and resource use must be assessed systematically within the framework of materiality analysis and presented transparently using meaningful metrics.

This creates the need to establish an indicator system that adequately reflects the complex interrelationships of the circular economy.

The core function of CE indicators is to make resource inflows and outflows measurable — including:

- Production materials

- Packaging

- Infrastructure

- Machinery

- Water

These indicators enable traceable, comparable, and consistent reporting that both meets regulatory requirements and reveals operational optimization potential.

Examples of practice-relevant CE indicators include, among others:

Circular Economy Performance Indicator (CPI) and Recyclability Benefit Rate (RBR)

The Circular Economy Performance Indicator (CPI) and the Recyclability Benefit Rate (RBR) are two established metrics for assessing the ecological effectiveness of recycling processes. In this context, both indicators quantify the ratio between the potential environmental relief that can be achieved through the recycling of a product and the environmental impacts associated with producing the same product from primary raw materials and its subsequent disposal.

The concepts are based on scientific works by Huysman et al. (2017) and Ardente and Mathieux (2014) and provide a sound foundation for integrating circular performance indicators into corporate sustainability assessments.

Reuse Potential Indicator (RPI)

The Reuse Potential Indicator (RPI) describes the potential for reusing components within a product family. It measures the extent to which parts or modules can be reused across different product variants without fundamental modifications. The indicator thus provides valuable insights into the design flexibility and reusability of technical systems, particularly in the context of modular product concepts.

The methodological foundation goes back to the work of Mesa et al. (2018) and helps companies systematically evaluate circular strategies such as reuse or remanufacturing early in the product development process.

Material Circularity Indicator (MCI)

The Material Circularity Indicator (MCI) was developed by ANSYS Granta in collaboration with the Ellen MacArthur Foundation and is used to assess the extent to which the material flows of a product can shift from a linear to a circular, resource-efficient usage path.

The calculation is based on three key parameters:

- 𝑉: mass of primary raw materials used for production

- 𝑊: mass of non-recoverable waste attributable to the product

- 𝑋: utilization factor, which describes the duration and intensity of product use

The calculation is carried out in two steps:

MCI = 1 – [LFI * F(x)]

Linear Flow Index (LFI) = (V+W)/(2*M)

F(X) denotes the utilization factor as a function of usage X, with M representing the mass of the product.

Other Key Indicators

In addition to the metrics already mentioned, there are numerous other indicators that can be used to assess circularity. A prominent example is the Circular Economy Index (CEI), which measures the ratio of the market value of materials recovered through recycling to the value of the originally used raw materials.

Furthermore, metrics such as the Product-Level Circularity Metric (PCM), the Circular Economy Toolkit (CET), the Circular Economy Indicator Prototype (CEIP), the Input-Output Balance Sheet (IOBS) method, the Eco-efficient Value Ratio (EVR), the Resource Duration Indicator (RDI), and the Cradle-to-Cradle Material Reutilization Indicator offer differentiated approaches to capturing circularity performance at the product, process, or company level.

These indicators are gaining importance not only for strategic management within companies but are also relevant for investors, regulatory authorities, and the management of global value chains and supply chains.

Methodological Approaches to Assessing Circular Economy

Assessing circular economy performance in companies requires a methodological approach that takes into account both measurable metrics and qualitative assessments. The aim is to determine the level of development of circular measures, systematically analyze material flows, and identify potential efficiency gains.

The choice of methodology depends on factors such as company size, industry, data availability, and regulatory requirements. A sound performance assessment enables targeted improvement measures to be derived, their impact to be tracked, and the results to be communicated transparently to relevant stakeholders

Material Flow Analyses (MFA) & Life Cycle Assessment (LCA)

Material Flow Analyses (MFA) are used to make the path of raw materials and resources within a company or along the entire value chain transparent. They help identify inefficient processes and pinpoint opportunities for improved resource use. MFA is often combined with Life Cycle Assessment (LCA) to capture the environmental impacts of a product throughout its entire life cycle. In addition, input-output analyses provide an overview of circular-oriented systems and their economic interrelationships.

Maturity Models & Qualitative Assessments

Maturity models offer a structured way to qualitatively assess the progress of circular initiatives. They use questionnaires and evaluation matrices to assign companies to specific stages depending on their level of development. Models such as the maturity model developed by EFS (here you can test the EFS maturity model for measuring and promoting circular value creation for free and determine your score) provide a conceptual framework for quantitatively capturing and evaluating progress in the area of circular value creation.

The structured application of such frameworks also facilitates access to internal and external financing for sustainable initiatives. Typically, these models consist of several stages that enable the step-by-step development of processes and capabilities.

Methods for Measuring Environmental Aspects

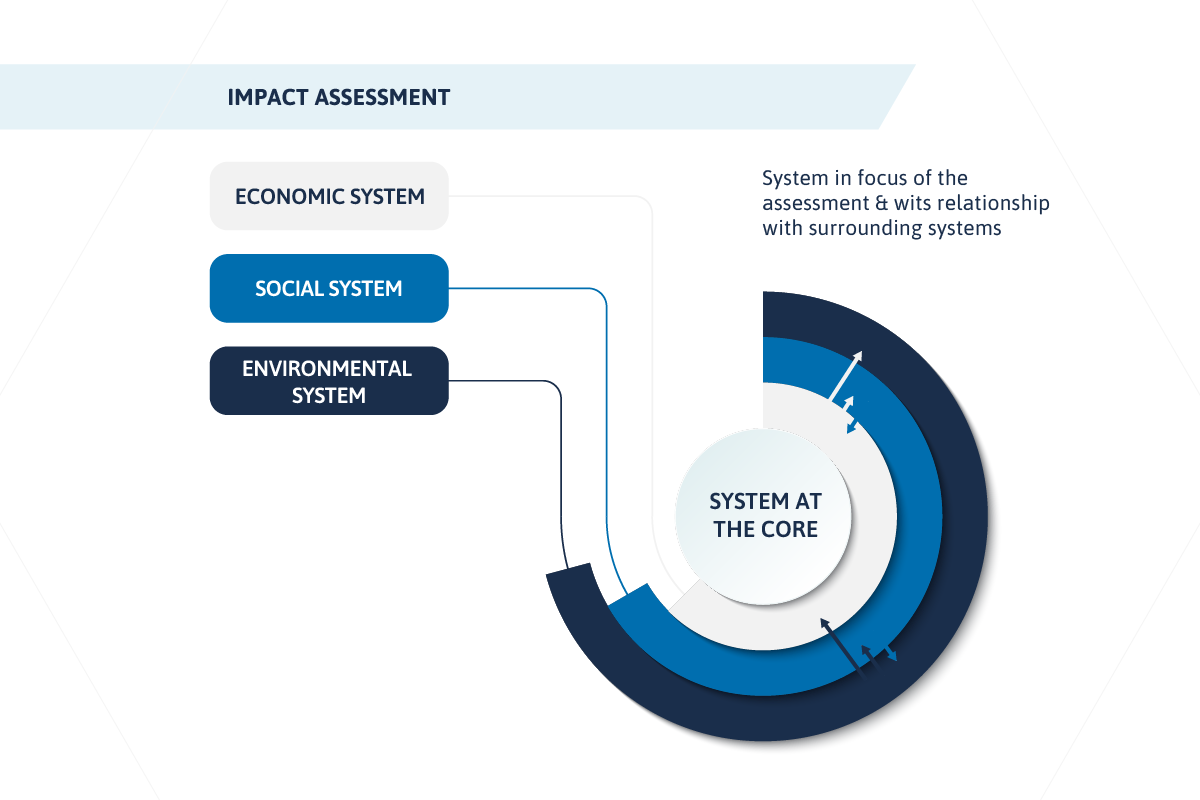

In principle, circular economy strategies aim to reduce environmental impacts, but they can also involve potential goal conflicts. Therefore, a complementary environmental assessment is always recommended. The literature suggests various approaches for a comprehensive assessment of all three dimensions of sustainability, including the Circular Life Cycle Sustainability Assessment by Luthin and the use of Multi-Criteria Decision Analysis (MCDA) as proposed by Niero.

To holistically assess the ecological, economic, and social impacts of circular strategies, it is necessary to extend indicators beyond product-specific properties such as durability, recyclability, and reparability. The assessment of circular systems thus goes beyond merely capturing circularity and includes a comprehensive impact analysis. It must be ensured that the analysis is consistent with the chosen system level (macro, meso, or micro level) and the defined system boundaries.

Digital Technologies for Data Collection

In addition, digital technologies make a significant contribution to improving data availability and quality, thereby laying the foundation for informed, resource-efficient decisions. A holistic approach that combines digital transformation, circular metrics, and sustainability goals is crucial to enhancing the effectiveness of circular economy models.

Key technologies include the Internet of Things (IoT), which enables precise monitoring of resource flows; artificial intelligence (AI), which supports data-driven process optimizations; blockchain technology, which ensures transparency and traceability along the product life cycle; and robotics, which contributes to efficiency gains and waste reduction through automation. Thus, digitization not only increases operational performance but also expands the analytical capabilities for systematically assessing and managing circular strategies.

Conclusion

Assessing measures in the spirit of the circular economy places high methodological demands: it must integrate ecological, economic, and social dimensions, reflect systemic interrelationships, and at the same time be applicable to business practice and regulatory requirements. Despite the abundance of available indicators, there is often a lack of comparability, data consistency, and practical applicability.

What is needed is a shared understanding of the requirements for effective CE indicators — as well as an application-oriented, scalable framework for the comparable measurement of circular performance. This is precisely where professional consulting comes in: providing methodological clarity, strategic prioritization, and the development of tailored assessment models.

FAQs

How is a circular economy measured?

The circular economy is measured using specific indicators that capture resource use, recycling rates, and material efficiency — supplemented by comprehensive assessments of ecological, social, and economic impacts.

What criteria should be used to select the right CE indicators?

The indicators should be relevant, measurable, comparable, and practically applicable, and they should enable a holistic view of the product or system.

How does the Material Circularity Indicator (MCI) work?

The MCI assesses the extent to which a product shifts from a linear to a circular material flow. It is based on the proportion of primary raw materials, non-recoverable waste, and the product’s usage duration.